Overhead cranes are impressively diverse mechanisms used to lift, lower, and generally transport loads of various shapes, sizes, and weights. Also, commonly known as lifting cranes or hoist cranes, most overhead cranes can crane and hoist and loads that weigh up to approximately 1,000 tons. Read More…

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

As a Factory Authorized R&M Master Distributor and Crane Builder, Wolverine provides its customers with the finest production built crane components available. Some of the products we provide include gantry cranes, overhead cranes, chain and wire rope hoists and much more. Regardless of your needs, we design, build, and install custom systems to fit any process or application.

At TC/American Crane Company, we design, manufacture, and support custom crane systems that deliver reliability, precision, and long-term performance across a wide range of industrial environments. As pioneers in the field, we bring decades of engineering expertise to every overhead lifting solution we create, integrating innovative track systems, patented components, and tailored configurations...

Our hundreds of pre-engineered cranes can be cost-effectively customized by our certified engineers for unusual applications, including low ceilings, obstacles, and atypical capacities. All Spanco cranes come with the best warranties in the industry.

More Crane Manufacturers

Overhead cranes, often referred to as hoist cranes, industrial lifting cranes, or bridge cranes, are highly adaptable material handling systems engineered to lift, lower, and horizontally move loads of diverse shapes, sizes, and weights. With lifting capacities reaching up to 1,000 tons, these cranes are an indispensable asset in both commercial and heavy industrial environments. Overhead cranes operate using hydraulic systems, internal combustion engines, or electric motors and batteries, offering reliable solutions for a wide range of applications. Key sectors that rely on overhead crane systems include paper mills, automobile manufacturing plants, steel refineries, aerospace facilities, shipyards, and logistics centers. Common uses involve constructing and maintaining paper machinery, handling heavy press rolls, managing raw materials, storing and moving hot metal, and refining steel or aluminum.

Are you looking for the best overhead crane manufacturers or want to understand which crane type fits your application? Continue reading to explore crane types, benefits, buying considerations, and how to select a supplier that meets your operational needs.

History of Cranes

The origins of the modern industrial crane trace back to 6th century BC Greece, where the Archaic Greeks began using winch and pulley hoists in construction, moving away from labor-intensive ramps and primitive lifting devices. The subsequent invention of the compound pulley marked a pivotal advancement, allowing heavier loads to be lifted with less effort. After the Roman Empire era, further developments in winch and pulley systems gave rise to the treadmill crane, which remained prevalent throughout the Middle Ages.

The Industrial Revolution sparked transformative changes in crane technology. In 1838, William Armstrong developed the first hydraulic water-powered crane, offering unprecedented lifting power for its time. German manufacturers soon began mass-producing overhead cranes, setting new benchmarks for efficiency in factories and shipyards. The late 19th and early 20th centuries saw further innovation with the introduction of electric motors, internal combustion engines, and steam engines. The first steam-powered overhead crane, installed by John Ramsbottom at the Crewe Railway workshop in 1860, was followed by Sampson Moore’s electric overhead crane in 1876. This pioneering crane operated at the Royal Arsenal in Woolwich, London, for over a century before being retired and displayed in Birmingham, Alabama. The concept of the tower crane first entered construction sites in 1908, revolutionizing how skyscrapers and large structures were built.

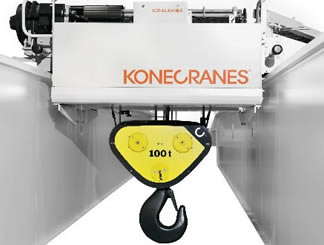

Crane designs became even more versatile in the mid-20th century. After World War II, Hans Liebherr and his team in Germany invented the first mobile cranes, introducing unprecedented flexibility and mobility for construction and industrial applications. Today, leading crane manufacturers such as Gorbel Inc., Konecranes, and Demag produce overhead cranes that are robust, modular, and adaptable, meeting the diverse and evolving needs of modern industry.

How Cranes Work

Regardless of the specific type, overhead cranes—also known as bridge cranes or industrial lifting cranes—utilize pulleys and cables to hoist, lift, lower, carry, and precisely position heavy loads. Central to the crane’s structure are one or two overhead steel beams (girders), which provide critical support and stability. Additional mechanisms such as counterweights, hydraulic cylinders, chain hoists, levers, and pivoting arms may be incorporated to enhance operational flexibility and efficiency.

Curious about which crane suits your facility? Explore the various types below to find the best solution for your material handling challenges.

Types of Cranes

Overhead cranes are available in numerous configurations to match a wide array of industrial and commercial needs. The most common types include stacker cranes, jib cranes, gantry cranes, and bridge cranes.

Stacker cranes are designed for automated storage and retrieval, moving vertically or horizontally on tracks to access and transport items within inaccessible warehouse aisles or high-density storage systems. Frequently deployed as forklift alternatives or in CNC-operated environments, stacker cranes are critical in logistics, distribution centers, and automated warehouses where space optimization and efficiency are top priorities.

Jib cranes are compact workstation cranes ideal for localized lifting tasks. They are frequently used for assembling military vehicles, automotive parts, and in general manufacturing. Featuring a movable hoist on a rotating jib (vertical support), jib cranes can be wall-mounted or free-standing, rotating 180–360 degrees depending on configuration. Their space-saving, cost-effective nature makes them ideal for small work cells, maintenance bays, and where floor space is limited.

Gantry cranes are built atop two or more movable support structures known as gantries that straddle a workspace or load. Types include full gantry, semi-gantry (supported by one leg and a counterbalance), portable gantry, rubber tyred gantry (RTG), and workstation gantry cranes. Gantry cranes excel in outdoor and large-scale environments—such as shipbuilding, bridge construction, container yards, and railyards—where their mobility and capacity to handle oversized or heavy items are essential. Portable gantry cranes and workstation gantries are used for lighter materials in tight indoor spaces.

Unlike bridge cranes, gantry cranes support trolleys and hoists on legs that move along fixed rails on the ground, eliminating the need for building-integrated runways. Their robust construction makes them indispensable in shipyards, metalworking, monument construction, and large vehicle assembly.

Bridge cranes, also called track cranes, are fixed structure cranes that feature two parallel overhead runways integrated into the building’s support system. The bridge spans the gap and supports a trolley-mounted hoist, allowing for precise vertical and horizontal load movement. Bridge cranes are available in single or double girder configurations. Single girder systems are lighter and more economical, while double girder bridge cranes support higher capacities and longer spans. They are the preferred choice for manufacturing facilities, assembly lines, steel mills, and warehouses requiring reliable in-facility material handling.

Bridge cranes are subdivided into process cranes (for heavy-duty, high-frequency, and high-capacity applications like steel or automotive plants) and modular cranes (for lighter, less demanding environments such as machine shops or smaller facilities). Their ability to improve workflow, reduce manual handling, and maximize workspace safety makes them essential for modern material handling and manufacturing operations.

Tower cranes are specialized for construction and demolition, recognized by their tall mast, fixed base, and a slewing unit enabling full rotation. These cranes are vital for constructing skyscrapers, bridges, and large infrastructure projects, offering exceptional height and reach. Mobile cranes encompass any crane mounted on a vehicle, ship, or aircraft for enhanced portability. Rubber-tyred gantry cranes (RTGs) are a specific mobile variant used for container stacking in ports and intermodal yards.

Overhead shop cranes are crucial in automotive and mechanical workshops for lifting engines, transmissions, and other vehicle components, enabling safe, ergonomic access to the undersides of vehicles. These shop cranes come in a variety of custom configurations, allowing for precise and secure handling of heavy loads during maintenance and assembly.

In addition to automotive and manufacturing applications, overhead cranes facilitate efficient loading and unloading of materials from trucks, streamline movement of inventory within facilities, and support die flipping, mold handling, and material feeding in stamping or injection molding operations. They are also fundamental to port operations, steel production, and bulk material handling.

For users seeking maximum lifting performance, electric wire rope hoists are a popular choice. These motor-driven hoists can be mounted to ceilings or single girders and are designed to raise exceptionally heavy loads using durable, flexible wire rope. They offer precision control and are often integrated into bridge or gantry crane systems.

Workstation cranes are engineered for ergonomic, repetitive lifting in light-duty environments. Options include free-standing or ceiling-mounted systems, with under-running or over-running configurations. Their modular design makes them ideal for assembly lines, packaging, or repair stations, reducing strain and improving operator safety.

Monorail cranes operate on a single overhead track, making them suitable for production and assembly lines where loads must be transported in a fixed, linear path. These cranes can incorporate switches, curves, and elevation changes for flexible routing in manufacturing, food processing, or distribution facilities.

Crane Equipment Components

Overhead cranes, also known as bridge cranes, are vital equipment in industrial and commercial settings for lifting, lowering, and transporting heavy loads with safety and efficiency. Their design comprises several critical components that work together to deliver operational reliability. Understanding the function of each part—such as the bridge, hoist, crane attachment, trolley, runway, end trucks, bumpers, and control systems—is key for operators, maintenance teams, and buyers. Below we explore these components in detail, providing insight to help you select, operate, and maintain the right crane for your facility.

-

- The Bridge: The Core Structural Component

The bridge is the central load-bearing beam or series of beams that span the workspace, providing structural integrity and enabling the crane to traverse the facility. Bridges are typically constructed from high-strength rolled steel and are engineered to support both the crane’s own weight and the maximum rated load.

-

- Single and Double Girder Designs: Single girder bridges are lighter, cost-effective, and suitable for loads up to 20 tons, while double girder bridges handle higher capacities—sometimes exceeding 1,000 tons—and allow for longer spans across large facilities.

- Steel Box Fabrication: In heavy-duty applications, bridges may be constructed from welded box girders for added rigidity and load distribution, common in steel mills and refineries.

- Benefits: The bridge’s robust design ensures minimal deflection, durability, and adaptability to various facility layouts, making it a fundamental element in safe material handling.

-

- The Hoist: The Lifting Mechanism

The hoist is the heart of the overhead crane, responsible for raising, lowering, and holding loads. Mounted on the bridge’s trolley, the hoist can be powered manually, via electric motors, or pneumatically. Electric wire rope hoists and chain hoists are the most common in industrial settings.

-

- Connection and Operation: The hoist attaches the load—via a hook, fork, or other attachment—using a wire rope, chain, or cable. It may be operated with precise controls for sensitive or high-value items.

- Types of Hoists: Options include wire rope hoists (for heavy, repetitive lifts), chain hoists (for lighter, more precise tasks), and pneumatic hoists (for hazardous or explosive environments).

- Benefits: The hoist enables safe, controlled movement of heavy materials, reducing manual labor and risk of injury.

-

- Crane Attachments: Customizable Load Handling

Attachments at the end of the hoist allow the crane to handle a wide variety of loads. The most common is the hook, but specialized tools increase task flexibility.

-

- Types of Attachments: Hooks (for general lifting), forks (pallet handling), augers (bulk materials), grapples (scrap metal, irregular items), and lifting magnets (ferrous materials).

- Customization: Attachments can be tailored or swapped for specific industries—such as hot-metal lifting in foundries or fragile material handling in electronics.

- Benefits: This adaptability maximizes the crane’s value and application range.

-

- The Trolley: Enabling Horizontal Movement

The trolley is a motorized or manual carriage that moves the hoist laterally along the bridge. This allows for precise horizontal positioning of loads.

-

- Top Running Trolleys: Ideal for heavy loads, running on rails atop the bridge.

- Under Running Trolleys: Offer flexibility in low-headroom environments by running beneath the bridge girder.

- Features: Some trolleys include booms for increased reach, or variable-speed drives for accurate positioning.

-

- The Crane Runway: The Structural Foundation

The runway is the track or beam system supporting the bridge, allowing the crane to traverse the length of the facility. Runways are typically integrated into the building structure and equipped with steel rails for durability.

-

- Benefits: Runways enable full facility coverage and efficient material flow in manufacturing, warehousing, or maintenance environments.

-

- End Trucks: Facilitating Bridge Movement

End trucks are assemblies at each end of the bridge, equipped with wheels or rollers that allow the bridge to move smoothly along the runway rails.

-

- Wheel Configurations: More wheels distribute heavier loads, prevent rail damage, and ensure stability.

- Power and Control: Typically driven by electric motors for smooth, controlled motion.

-

- Bumpers: Enhancing Safety and Durability

Bumpers are shock-absorbing devices at the ends of the crane’s travel path. They minimize impact, reduce wear, and prevent collisions with facility walls or other cranes.

-

- Benefits: Essential for safety, especially in high-speed or heavy-duty applications, and for protecting structural components.

-

- Control Systems: Managing Crane Operations

Controls are the operator interface for all crane movements. Modern cranes utilize advanced control systems for improved safety and efficiency.

-

- Control Panels and Pendants: Manual or remote operation via joysticks, buttons, or touchscreens.

- Radio Remote Controls: Allow operators to manage cranes safely from a distance, especially in hazardous environments.

- Automation and Sensors: Load detection, collision avoidance, and positioning sensors for automated or semi-automated cranes.

Benefits of Overhead Cranes

Overhead cranes deliver a wealth of advantages over alternative lifting equipment. Their benefits include:

- Efficiency: Overhead cranes can move extraordinarily heavy loads with minimal energy consumption. Their streamlined design, with few moving parts, allows for rapid material transport, reducing cycle times and workforce requirements.

- Safety: Wireless controls and ergonomic design keep operators at a safe distance from suspended loads, reducing injury risk. Properly maintained overhead cranes drastically lower the incidence of on-site accidents compared to forklifts or manual lifting, especially in hazardous or high-traffic environments.

- Versatility: With the ability to accommodate various attachments and adapt to new tasks, overhead cranes serve multiple functions—handling raw materials, finished products, heavy machinery, or fragile loads. They’re suitable for indoor and outdoor use, with custom options for unique environments.

- User-Friendliness: Most overhead cranes are intuitive to operate, requiring just a few days of training. This short learning curve increases productivity and reduces onboarding costs.

- Cost Savings: By reducing labor needs and minimizing maintenance, overhead cranes offer long-term operational savings. Their reliability leads to fewer breakdowns and lower repair costs than more complex mobile equipment.

Want to know how overhead cranes can optimize your workflow or reduce your facility’s operating costs? Contact a crane manufacturer or request a facility assessment to discover the right solution.

Crane Design and Customization

Overhead crane manufacturers custom-design each system based on application-specific requirements such as workspace size, load characteristics, frequency of use, environmental conditions, and compliance standards. Key considerations include:

- Crane Type and Configuration: Selecting between single vs. double girder, fixed vs. mobile, and indoor vs. outdoor designs.

- Load Capacity and Span: Determining required lifting power and bridge length based on workflow and facility layout.

- Power Source: Choosing between electric, hydraulic, or engine-driven options for efficiency and compatibility.

- Attachments and Controls: Customizing end-effectors, automation, and operator interfaces for specialized tasks.

Manufacturers provide a wide range of options, including corrosion-resistant coatings, explosion-proof motors, and advanced safety systems, to ensure your overhead crane meets every operational demand. For example, bridge cranes can be delivered as either single or double girder systems to match the required winch hardware height and load ratings.

The Future of Remote Crane Monitoring Systems

The evolution of wireless remote crane management and monitoring systems is transforming crane operation, maintenance, and safety. These IoT-enabled platforms provide operators and maintenance teams with real-time data on crane performance, usage patterns, load weights, and potential faults.

- Operational Forecasting: Access to live data enables predictive maintenance, reducing unplanned downtime and improving overall equipment effectiveness (OEE).

- Productivity Gains: Automated alerts and performance analytics streamline workflow and facilitate rapid troubleshooting.

- Safety Enhancements: Continuous monitoring detects overloads, improper usage, or mechanical issues, preventing accidents before they occur.

- Cost Reduction: Remote diagnostics and digital reporting minimize the need for on-site inspections, reducing labor costs and maximizing uptime.

Future advancements in crane technology—such as smart service panels, automated positioning, and integration of recyclable materials—are making cranes more compact, efficient, and environmentally friendly. As wireless systems become standard, expect improvements in safety, scalability, and operational insight for businesses of all sizes.

Is your facility ready for the next generation of smart crane solutions? Reach out to a manufacturer specializing in remote monitoring systems to future-proof your investment.

Choosing the Right Overhead Crane

Selecting the right overhead crane is a strategic decision that directly impacts production efficiency, safety, and long-term costs. Considerations include:

- Cranes’ Motion and Application: Do you need linear, rotational, or multidirectional movement? Assess load type, weight, and fragility.

- Environmental Factors: Will the crane operate indoors, outdoors, in corrosive, high-temperature, or explosive environments?

- Usage Frequency: Is the crane for continuous, intermittent, or light-duty use? This affects the required durability and service class.

- Customization Needs: Are specialized attachments, automation, or integration with existing systems needed?

Consult a reputable crane manufacturer to conduct a site survey and recommend the optimal crane type and configuration for your unique requirements.

Crane Safety and Compliance Standards

Ensuring the longevity and safe operation of overhead cranes relies on rigorous maintenance and compliance with industry standards, such as those established by OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute). Key safety and compliance practices include:

- Monthly inspections of running ropes, hoist chains, and end connections for wear, fraying, or damage.

- Daily checks of hydraulic and pneumatic systems for leaks, and mechanical components for proper adjustment.

- Regular assessment of hooks, drums, sheaves, brakes, and electrical systems for cracks or malfunction.

- Keeping a maintenance kit ready for quick replacement of worn parts.

- Ensuring only certified, trained personnel operate cranes due to the inherent risks and complexity.

For in-depth information on OSHA and ANSI crane safety standards, or to schedule safety training, contact a certified crane inspection specialist.

Mobile Elevated Work Platform Inspection

Mobile Elevated Work Platforms (MEWPs) play a crucial role in warehouses and industrial facilities, allowing personnel to work safely at height. Comprehensive inspection programs and OSHA-compliant training ensure MEWP reliability and prevent accidents. These courses educate employees on maintenance, inspection protocols, and documentation of faults, further enhancing workplace safety.

OSHA Safety Certificate

An OSHA Safety Certificate is vital for workplace safety in both construction and general industry. Certification equips staff with the knowledge to identify and mitigate hazards, interpret federal regulations, and implement tailored safety protocols. Regular recertification and adherence to evolving OSHA standards maintain compliance and protect your workforce.

Things to Consider About Cranes

When purchasing an overhead crane, partnering with a reputable, experienced manufacturer is essential. An ill-suited or poorly designed crane can result in operational inefficiency, costly downtime, or even serious accidents.

To find a trustworthy manufacturer, review the profiles in our recommended listings. Clearly define your specifications, budget, delivery timeline, and compliance requirements. Compare these with the offerings of shortlisted companies, and reach out—preferably by phone—to assess responsiveness and customer service. Evaluate proposals based on technical merit, support, and value before making your final choice.

Ready to start your search? Browse more crane manufacturers or use the steps below to streamline your buying process.

How to Select a Crane Manufacturer

Selecting the right crane manufacturer is a pivotal decision for industries such as manufacturing, construction, steel production, logistics, and warehousing, where cranes are essential for material handling. From overhead and gantry cranes to jib and mobile cranes, your chosen supplier must deliver solutions that meet operational, safety, and environmental requirements. IQSDirectory.com is a comprehensive online directory connecting buyers to top-rated North American crane manufacturers, simplifying the selection process. Use the following guide to navigate your options and choose a partner capable of delivering quality, customized crane solutions.

Step 1: Define Your Crane Requirements

Clearly outline the type of crane needed—overhead, gantry, jib, or mobile—along with load capacity, application, and environmental considerations. Assess whether specialized features (such as explosion-proof construction, automation, or corrosion resistance) are necessary.

- Crane Type and Application: Are you in manufacturing, steel production, or logistics? Do you need a crane for container handling, automotive assembly, or hot metal transfer?

- Load Capacity: Determine the heaviest load and frequency of lifts.

- Environmental Conditions: Consider indoor/outdoor use, exposure to chemicals, or temperature extremes.

- Power Source: Electric, hydraulic, or engine-driven options must align with site infrastructure.

- Compliance: Ensure all solutions comply with OSHA, ANSI, and industry-specific standards.

Having these requirements in mind allows you to filter manufacturers on IQSDirectory.com by relevant solutions.

Step 2: Navigate to the Crane Manufacturer Category on IQSDirectory.com

Visit IQSDirectory.com, then use the search bar or browse by category (e.g., “overhead crane manufacturers,” “gantry crane manufacturers,” “jib crane manufacturers,” etc.). Filter results by state or region to find suppliers near you, reducing lead times and supporting local service.

Step 3: Explore Manufacturer Profiles and Previews

Manufacturer listings feature website previews, detailed profiles, and customer reviews. Browse these to compare product ranges, customization capabilities, and industry experience. Look for manufacturers specializing in your application or offering turnkey solutions, such as custom bridge cranes or rapid-delivery floor cranes.

Step 4: Evaluate Manufacturer Experience and Expertise

Assess each supplier’s track record, customer feedback, and engineering capabilities. Favor companies with in-house design and fabrication teams, experience in your sector (e.g., steel mills, auto plants), and proven reliability on similar projects.

Step 5: Request Quotes and Compare Options

Use the “Request a Quote” tool to contact multiple manufacturers simultaneously. Provide detailed specifications to ensure accurate and comparable quotes. Evaluate offers based on pricing, delivery, value-added services (customization, installation, after-sales support), and warranty terms.

Step 6: Verify Manufacturer Reputation and Support

Use IQSDirectory’s company profiles and newsroom to check for up-to-date information, news coverage, and customer testimonials. Directly contact manufacturers to discuss project experience, support services, and ongoing maintenance or spare parts availability.

Step 7: Consider Geographic Proximity and Delivery Speed

Local manufacturers often provide faster delivery, reduced shipping costs, and more accessible service. Use geographic filters to prioritize suppliers in your state or region.

Additional Tips for Using IQSDirectory.com

- Explore related categories (e.g., “Industrial Cranes,” “Track Cranes”) for alternative options.

- Share profiles with your team or on social media to gather feedback.

- Provide feedback to IQSDirectory to enhance the platform and your user experience.

Why Use IQSDirectory.com to Find a Crane Manufacturer?

- Targeted, industry-specific search results for material handling equipment.

- Comprehensive manufacturer profiles, reviews, and product media for informed comparisons.

- Patented tools for efficient quote requests and website previews.

- Geographic filtering to match local suppliers with your project timeline and support needs.

Ready to find the perfect crane solution for your facility? Browse more crane manufacturers or start your targeted search on IQSDirectory.com today!

What are overhead cranes and where are they commonly used?

Overhead cranes, also called hoist cranes or bridge cranes, are material handling systems designed to lift, lower, and move loads horizontally. They are widely used in industries like paper mills, automotive plants, steel refineries, aerospace facilities, shipyards, and logistics centers for tasks such as moving heavy materials, machinery, and raw goods.

What are the different types of overhead cranes?

Common types include stacker cranes, jib cranes, gantry cranes, bridge cranes, tower cranes, workstation cranes, and monorail cranes. Each type is designed for specific applications and environments, ranging from automated warehouses and assembly lines to outdoor construction and large-scale industrial sites.

What are the main components of an overhead crane?

Key components include the bridge (structural beam), hoist (lifting mechanism), crane attachments (such as hooks or magnets), trolley (moves the hoist horizontally), runway (supports crane movement), end trucks (allow for bridge movement), bumpers (enhance safety), and control systems (for operations and automation).

What are the benefits of using overhead cranes?

Overhead cranes offer efficiency, safety, and versatility. They enable rapid transport of heavy loads, minimize manual labor, reduce workstation accidents, adapt to various attachments and tasks, and usually require less maintenance and training than alternative lifting solutions.

How do I choose the right overhead crane for my facility?

Consider application requirements such as motion type, load weight, environmental conditions, frequency of use, and whether customization is needed. Consulting with a reputable crane manufacturer to conduct a site survey and analyze your needs ensures the best crane type and configuration for your operation.

Why are remote monitoring systems important for overhead cranes?

Remote monitoring systems provide real-time data on crane performance, enable predictive maintenance, improve safety through automated alerts, and allow for operational forecasting. These IoT-enabled tools help reduce downtime, enhance productivity, and ensure preventive maintenance for long-term reliability.

What safety standards must overhead cranes comply with?

Overhead cranes must comply with industry safety standards set by OSHA and ANSI. This includes regular inspections, proper maintenance of mechanical and electrical systems, operator training, and following strict operational and documentation protocols to ensure safe and compliant usage.

How do I select a reputable crane manufacturer?

Define your requirements, compare manufacturers’ expertise and customer service, review compliance and past projects, and request quotes. Reputable manufacturers offer detailed profiles, strong customer feedback, and comprehensive support throughout the buying, installation, and maintenance processes.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches