In factory floors, warehouses, store yards and other areas where heavy equipment or supplies must be regularly moved from one place to another, permanent industrial cranes make possible the easy and safe movement of objects. Read More…

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

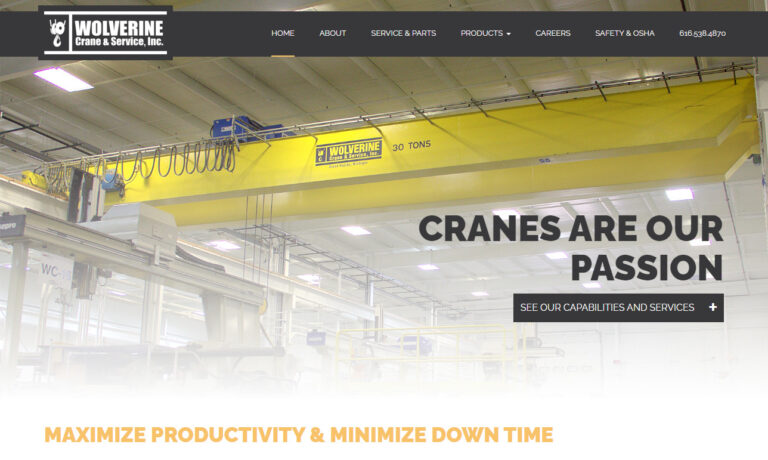

As a Factory Authorized R&M Master Distributor and Crane Builder, Wolverine provides its customers with the finest production built crane components available. Some of the products we provide include gantry cranes, overhead cranes, chain and wire rope hoists and much more. Regardless of your needs, we design, build, and install custom systems to fit any process or application.

At TC/American Crane Company, we design, manufacture, and support custom crane systems that deliver reliability, precision, and long-term performance across a wide range of industrial environments. As pioneers in the field, we bring decades of engineering expertise to every overhead lifting solution we create, integrating innovative track systems, patented components, and tailored configurations...

Our hundreds of pre-engineered cranes can be cost-effectively customized by our certified engineers for unusual applications, including low ceilings, obstacles, and atypical capacities. All Spanco cranes come with the best warranties in the industry.

More Bridge Crane Manufacturers

Bridge cranes are essential parts of many industrial operations. In the steel industry, bridge cranes are used to suspend and pour raw steel materials into furnaces. They are also used to remove shaped steel beams to storage areas as well as prepare them for shipment. Bridge cranes of variable sizes are used in the automotive industry for heavy duty and light duty fabrication processes.

In the paper milling industry, large rolls of paper are transported by bridge cranes for shipment and storage. Bridge cranes are an efficient, often higher-performance alternative to other load moving tools like fork-lifts and hi-lows. Mobile, floor-based load bearing tools like forklifts require enough clearance to move around effectively and safely.They also require independent energy sources like batteries or natural gas reservoirs, both of which can be expensive. Bridge cranes eliminate the need for using space in this way and can be permanently connected to power sources.

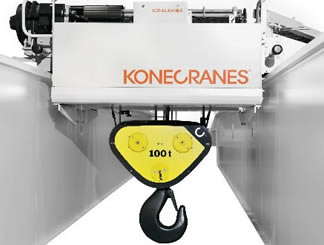

Bridge crane systems involve several parts, the most important of which is the crane itself. The crane involves a winch, which allows the lowering and retraction of tension cables down to workspace floors where they can be attached to loads. In more automated models, robotic arms are used instead of cables.

In either case, the crane mechanism is mounted on a specially designed steel girder, the ends of which are equipped with rollers. The girder moves forward and backward over two beams that are parallel to each other and perpendicular to the girder. The beams support the girder and the load from the crane. They also make the girder's movement possible.

The crane itself is also equipped with rollers, and it can move back and forth across the girder. The combination of lateral and linear motion gives the crane access to almost the entire floor in a workspace. In some cases, as is more common in outdoor, non-permanent materials movement operations, bridge cranes can be equipped with roller systems at the bottoms of their support beams, which allows for the entire mechanism to move relative to the ground.

Such designs can be assembled on site for construction purposes, waste area clean up and other heavy duty materials movement operations. Mobile bridge cranes are sometimes called gantry cranes, and stationary gantry cranes are sometimes described as bridge cranes. Generally, permanent, structurally supported parallel girder cranes are considered to be bridge cranes, while gantry cranes are more likely to be free standing and mobile.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

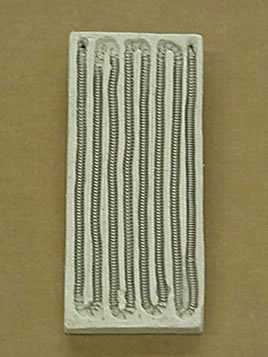

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches