A floor crane is a piece of lifting machinery similar to a crane. It comprises a hook that can lift and move loads. A floor crane is often used to swap out dies from a machine or press. As the load is hanging, fitting it on a machine or press is simple. Read More…

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

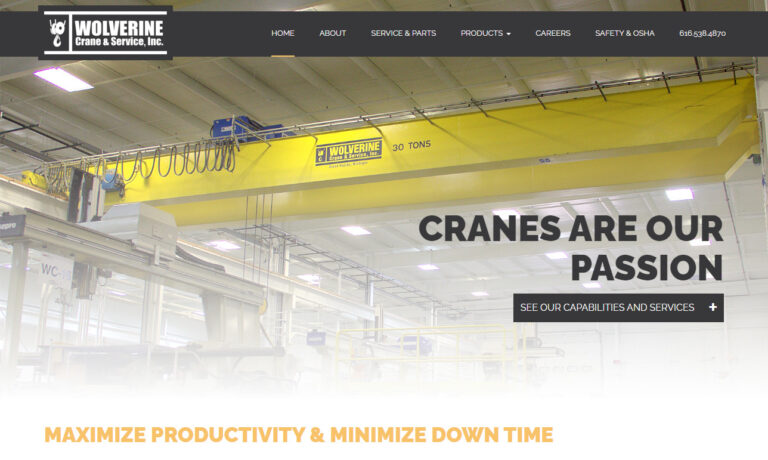

As a Factory Authorized R&M Master Distributor and Crane Builder, Wolverine provides its customers with the finest production built crane components available. Some of the products we provide include gantry cranes, overhead cranes, chain and wire rope hoists and much more. Regardless of your needs, we design, build, and install custom systems to fit any process or application.

At TC/American Crane Company, we design, manufacture, and support custom crane systems that deliver reliability, precision, and long-term performance across a wide range of industrial environments. As pioneers in the field, we bring decades of engineering expertise to every overhead lifting solution we create, integrating innovative track systems, patented components, and tailored configurations...

Our hundreds of pre-engineered cranes can be cost-effectively customized by our certified engineers for unusual applications, including low ceilings, obstacles, and atypical capacities. All Spanco cranes come with the best warranties in the industry.

More Floor Crane Manufacturers

Floor cranes provide workers with a safe and labor-saving alternative to using forklifts or other powered lift mechanisms to move and handle items. Cranes have sturdy and resilient designs to survive challenging circumstances. Floor lift cranes are often constructed of welded, heavy-duty steel.

All lifting devices use hydraulics in some capacity, ranging from the hand pump to motors. The hand pump version's lever or crank handle raises and lowers the load. The type of motor used in motorized hydraulic floor cranes varies according to the crane's weight capacity, ranging from a few hundred pounds to several hundred. The engine can be integrated into a 3 -4 hour battery pack or mounted on the crane. The crane can run continuously for eight hours in either situation.

Types of Floor Cranes

There are many wheel-mounted hydraulic cranes engineered to meet different requirements. The placement of the legs or supports concerning the jib can differentiate between types. The legs may be right beneath the jib or extend backward away from the jib. Close-lift hydraulic cranes have legs behind the jib so manufacturers can maneuver them close to the load.

The platform with wheels and legs is weighted to support and balance the load. The hydraulic pump is linked to the jib, and the legs of a typical floor hydraulic crane are extended out under the jib. This version does not need a counterbalance to keep the load steady and can be operated manually or with a motor.

Components of Hydraulic Floor Cranes

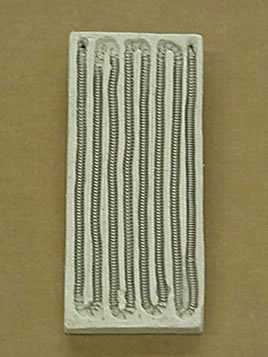

Hydraulic floor cranes have an oil rotor pump. A positive displacement pump called a rotary vane pump has vanes mounted on a rotor that revolves inside a hollow. The crane’s heavy arm supports the load. It is secured solidly to the base frame at one end and carries out tasks like load lifting. This design can be optimized to effectively carry different weights. The bearings are pressed smoothly into the shafts because they could shatter if pounded. The bearing is constructed of steel, while the bearing cap is made of mild steel.

How Hydraulic Floor Cranes Work

The rotor pump, directly connected to the motor shaft, activates when the AC motor is turned on. Pump activation elevates the oil in the reservoir, using the pump's suction pressure to reach the solenoid valve. The hydraulic cylinder is positioned between the frame and the lifting arm and is connected to the solenoid valve. Pressurized fluid flows into the cylinder when the operator opens the valve using a lever to retract the piston outward. As a result, the crane arm lifts the weight. The cylinder tends to retract backward when the portal is turned with a hand lever, which powers the arm to lift and move the load from one location to another.

Advantages of Hydraulic Floor Cranes

- Using a hydraulic crane instead of a manual one increases high load-carrying capability. Hydraulic floor cranes have a relatively simple design, so their maintenance is affordable.

- Hydraulic floor cranes can be operated with ease and little training.

- Since they take up less room, they can also be employed for small-scale applications.

Applications of Hydraulic Floor Crane

- Auto repair shops often use hydraulic floor cranes to move and reposition engines. Mobile hydraulic cranes are perfect for vehicle repair applications because they are affordable & intuitive to use. It is simple to lift engines, transport them to a repair facility, and inspect them.

- Due to their ease of positioning and manipulation compared to larger cranes, the use of mobile cranes has increased in warehouses and industries. In addition, similar to repair facilities, their affordability and adaptability make them the ideal solution for moving large materials.

Choosing the Right Floor Cranes Company

To make sure you have the most constructive outcome when purchasing Floor Cranes from a Floor Cranes Supplier, it is important to compare at least 6 Companies using our list of Floor Cranes suppliers. Each Floor Cranes Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Floor Cranes company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Floor Cranes businesses with the same quote.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches