Hoist cranes are essential pieces of machinery in various industries, including manufacturing, construction, warehousing, and logistics. These cranes use a hoist mechanism to lift and move heavy objects, making them ideal for moving materials from one location to another. Read More…

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

As a Factory Authorized R&M Master Distributor and Crane Builder, Wolverine provides its customers with the finest production built crane components available. Some of the products we provide include gantry cranes, overhead cranes, chain and wire rope hoists and much more. Regardless of your needs, we design, build, and install custom systems to fit any process or application.

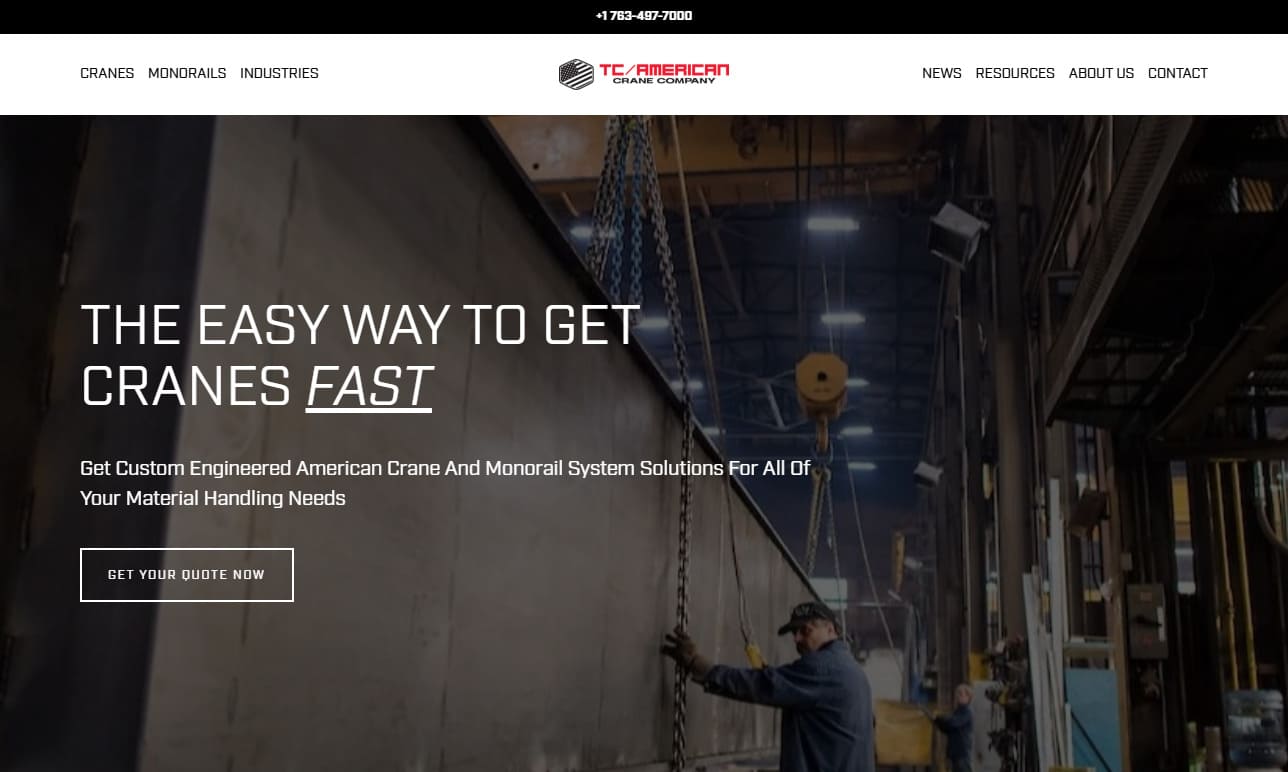

At TC/American Crane Company, we design, manufacture, and support custom crane systems that deliver reliability, precision, and long-term performance across a wide range of industrial environments. As pioneers in the field, we bring decades of engineering expertise to every overhead lifting solution we create, integrating innovative track systems, patented components, and tailored configurations...

Our hundreds of pre-engineered cranes can be cost-effectively customized by our certified engineers for unusual applications, including low ceilings, obstacles, and atypical capacities. All Spanco cranes come with the best warranties in the industry.

More Hoist Crane Manufacturers

Components of Hoist Cranes

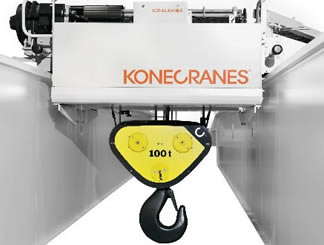

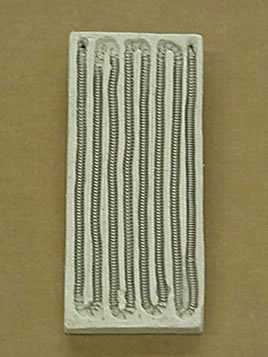

Hoist cranes are complex machines that require several components to function effectively. The hoist mechanism is the most crucial component of the crane, and it is responsible for lifting and lowering the load. It typically consists of a motor, gearbox, and drum or chain, which work together to move the load vertically. The trolley is another critical component that moves horizontally along the bridge to position the load accurately. The bridge is the structure that supports the trolley and hoist mechanism, and it runs along rails attached to the building or structure.

Electrical systems also play a vital role in the operation of hoist cranes. These systems include various motors, control circuits, and power supplies that ensure the crane operates smoothly and safely. The controls of the crane allow the operator to move the load in various directions and control the speed of the trolley and hoist mechanism. The safety features of hoist cranes are critical to preventing accidents in the workplace. These features include limit switches, emergency stop buttons, and overload protection, which prevent the crane from operating beyond its capacity.

All of these components work together to ensure that the hoist crane operates safely and efficiently. The hoist mechanism lifts and lowers the load, while the trolley and bridge move the load horizontally. The electrical systems and controls allow the operator to control the crane's movements accurately, while the safety features prevent accidents and damage to the crane and load. Understanding the various components of hoist cranes is crucial to ensuring that they operate correctly and safely.

Types of Hoist Cranes

Gantry cranes are a type of hoist crane that uses a bridge supported by two legs that run on rails or wheels. These cranes are ideal for moving heavy loads in and out of warehouses and factories. Jib cranes are another type of hoist crane that features a horizontal arm that pivots around a vertical column. They are ideal for lifting loads in confined spaces or where overhead cranes are the most common type of hoist crane and are used in a wide variety of applications, including manufacturing, construction, and mining. Wall-mounted cranes are similar to jib cranes but are attached directly to a wall. They are ideal for lifting loads in areas with limited space.

Considerations Regarding Hoist Cranes

One of the main considerations of hoist cranes is safety. These machines are powerful and can be dangerous if not used correctly. Manufacturers are working to combat this issue by incorporating safety features, such as limit switches and emergency stop buttons, into their designs. Another consideration is maintenance and repair, which can be costly and time-consuming. Manufacturers are addressing this issue by designing hoist cranes with easily replaceable parts and providing maintenance and repair services to their customers.

Benefits of Hoist Cranes

Hoist cranes offer several benefits that make them an essential tool for many industries. One significant benefit is their efficiency. Hoist cranes can lift and move heavy loads quickly and easily, reducing the time and effort required to move materials manually. They also offer cost-effectiveness, as they can move large loads with minimal labor, reducing the need for manual labor and increasing productivity. Another significant benefit of hoist cranes is their versatility. They can be used in a wide range of applications, from construction and manufacturing to mining and transportation. Hoist cranes can lift and move heavy loads in areas with limited access or overhead clearance, making them ideal for working in confined spaces or moving materials over obstacles.

Hoist cranes also offer safety benefits. They can reduce the risk of workplace injuries by allowing workers to move heavy loads without manual lifting, which can cause strain and injury. They also come equipped with safety features, such as limit switches and emergency stop buttons, which prevent accidents and damage to the crane and load. Finally, hoist cranes improve productivity by allowing workers to move materials quickly and efficiently. This can lead to increased output and revenue, as well as reduced labor costs.

Other benefits of hoist cranes include their ability to handle heavy loads that would be impossible to move manually. They also allow for precise positioning of loads, reducing the risk of damage to the load or surrounding areas. Additionally, hoist cranes can operate in a wide range of environments, from harsh outdoor conditions to temperature-controlled indoor settings.

Applications of Hoist Cranes

Hoist cranes are an essential tool for many industries, as they can lift and move heavy loads quickly and easily, reducing the time and effort required to move materials manually. As a result, hoist cranes are used in a wide range of applications, from manufacturing and construction to mining and transportation. In the manufacturing industry, hoist cranes are used to move heavy machinery and raw materials around the factory floor, increasing productivity and reducing labor costs. They are also used in the construction industry to move heavy building materials, such as steel beams and concrete, into place. In the mining industry, meanwhile, hoist cranes are used to extract ore and other materials from deep underground. They can lift and move heavy loads vertically, making them ideal for use in shafts and mines. Furthermore, hoist cranes are also commonly used in the transportation industry to load and unload cargo from ships and trucks.

In addition to these industries, hoist cranes are used in many other applications, such as in warehouses and distribution centers, in power plants and refineries, and in the entertainment industry for stage and lighting equipment. They are also commonly used in the oil and gas industry for offshore drilling operations.

The Future of Hoist Cranes

Looking to the future, advancements in technology will likely impact the design and functionality of hoist cranes. There is potential for increased automation, which could improve efficiency and productivity even further. Sustainability concerns may also impact the future of hoist cranes, as manufacturers look for ways to reduce their environmental impact such as exploring ways to incorporate sustainable materials and energy-efficient technologies in their designs in order to reduce their environmental impact. Finally, there is potential for increased safety features, such as collision detection and avoidance technology, which could make hoist cranes even safer to operate.

Choosing the Right Hoist Crane Manufacturer

To ensure you have the most positive outcome when purchasing a hoist crane from a hoist crane manufacturer, it is important to compare several companies using our directory of hoist crane manufacturers. Each hoist crane manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each hoist crane business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple hoist crane companies with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches