Using the overhead area of a manufacturing plant, an overhead crane is a form of heavy-duty machinery that can safely and accurately transport extremely large goods and equipment from one place to another. They are precisely constructed and intended to match a certain loading application because of the nature of their task. Read More…

We are Givens Lifting Systems, Inc., a leading company specializing in providing high-quality lifting solutions, with a primary focus on cranes. With our extensive expertise and commitment to innovation, we have established ourselves as a trusted partner for various industries worldwide.

PWI cranes are ready to help with any of your material handling needs. Our overhead bridge cranes are typically for heavy-duty material handling needs. Workstation cranes are lightweight and can be installed in any workspace. Jib cranes provide an excellent way to transfer material from on station to another. Gantry cranes work great for moving overhead cranes to different areas. Our team is...

Handling Systems International has become a premier leader in the crane manufacturers industry through our hard work and dedication. All of our cranes are built to fit the exact specifications of our customer's needs. We are committed to providing our customers with unbeatable service, high-quality products, and competitive prices.

As a Factory Authorized R&M Master Distributor and Crane Builder, Wolverine provides its customers with the finest production built crane components available. Some of the products we provide include gantry cranes, overhead cranes, chain and wire rope hoists and much more. Regardless of your needs, we design, build, and install custom systems to fit any process or application.

At TC/American Crane Company, we design, manufacture, and support custom crane systems that deliver reliability, precision, and long-term performance across a wide range of industrial environments. As pioneers in the field, we bring decades of engineering expertise to every overhead lifting solution we create, integrating innovative track systems, patented components, and tailored configurations...

Our hundreds of pre-engineered cranes can be cost-effectively customized by our certified engineers for unusual applications, including low ceilings, obstacles, and atypical capacities. All Spanco cranes come with the best warranties in the industry.

More Overhead Crane Manufacturers

Comprehensive Guide to Overhead Cranes: Types, Components, Applications, and Buying Tips

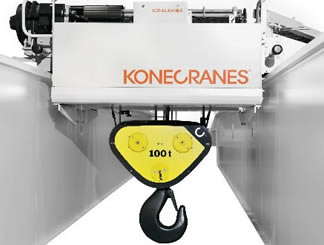

Overhead cranes, also known as bridge cranes or industrial cranes, play a vital role in modern material handling and heavy lifting operations across a wide range of industries. There are several sizes, styles, combinations, forms, and components for overhead cranes, designed to meet the diverse needs of manufacturing, warehousing, logistics, shipbuilding, automotive, steel production, and many other sectors. Whether you are looking for an efficient solution for moving heavy loads, enhancing workplace safety, or streamlining your workflow, understanding the various types, key features, and selection criteria for overhead cranes is essential.

What is an overhead crane? An overhead crane is a type of industrial lifting equipment used for loading and unloading, transporting objects, removing dies from stamping equipment, or feeding raw materials. These cranes are engineered to move heavy loads horizontally along overhead support structures, maximizing floor space and improving operational efficiency. If you’re researching best overhead crane solutions for your facility, or want to compare top-rated overhead crane manufacturers, this guide covers everything you need to know.

Why Choose Overhead Cranes? Efficiency, Safety, and Productivity

Efficiency and safety are the two basic justifications for deploying an overhead crane system. Overhead cranes can work much more quickly and with greater precision than land-based or floor-based equipment such as forklifts or pallet jacks. By lifting and transporting loads above ground level, overhead cranes eliminate many of the bottlenecks and hazards associated with manual material handling.

Safety is a key advantage of overhead cranes. When dealing with hot metals, chemicals, explosive substances, or toxic materials, overhead cranes can transfer items securely and without exposing personnel to risky, extreme situations. This reduces the likelihood of workplace injuries and helps companies comply with OSHA material handling standards and other safety regulations.

Are you concerned about workplace safety? Discover how industrial overhead crane systems can reduce injuries, improve ergonomics, and keep your facility compliant with safety guidelines.

Key Components of an Overhead Crane System

The modern overhead crane is a complex assembly of mechanical and electrical elements, engineered for durability and precision. The main components of an overhead crane include:

- Hoist: The hoist is the primary lifting mechanism, responsible for raising and lowering loads. Hoists can be electric, pneumatic, or manual, and often include wire ropes or chain drives.

- Trolley (Under Running / Underhung): The trolley moves the hoist horizontally along the bridge girder, allowing for precise positioning of the load.

- Top Running: Refers to overhead cranes whose trolleys run on rails mounted on top of the bridge girders, maximizing lifting height.

- Bridge (Single Girder or Double Girder): The bridge spans the width of the working area and supports the trolley and hoist. Single girder cranes are suitable for moderate loads and shorter spans, while double girder cranes are ideal for heavy-duty applications and longer spans.

- Runway Rail or Tracks: These are rails or tracks installed along the length of the facility, supporting and guiding the crane’s movement across the workspace.

- End Trucks: End trucks are wheel-mounted assemblies that support the bridge and enable it to travel along the runway rails.

- Bumpers: Safety devices designed to absorb impact and prevent collisions at the end of crane travel zones.

- Controls: Modern cranes use advanced controls, including pendant push-button stations, radio remote controls, or even automated PLC systems for enhanced precision and safety.

- Electrification: Power delivery systems (such as conductor bars or festoon cables) that provide electricity to the crane’s motors and controls.

Types of Overhead Cranes: Which Model Is Right for Your Application?

Overhead cranes are available in several configurations to suit facility layouts, load requirements, and specific use cases. Selecting the right type of crane is crucial for optimizing performance, maximizing safety, and ensuring long-term reliability.

-

Bridge Cranes

The most popular type of overhead crane is the bridge crane. Two overhead runway beams are connected to the building's support framework, allowing the crane bridge to traverse the working area. Bridge cranes are available in single girder and double girder configurations, with double girder models offering greater capacity and longer spans. They are ideal for manufacturing plants, warehouses, steel mills, and logistics centers.

- Capacity: Ranges from 1 ton to over 100 tons.

- Applications: Heavy lifting, assembly lines, shipping/receiving, automated material handling.

- Features: High precision, customizable spans, robust construction.

-

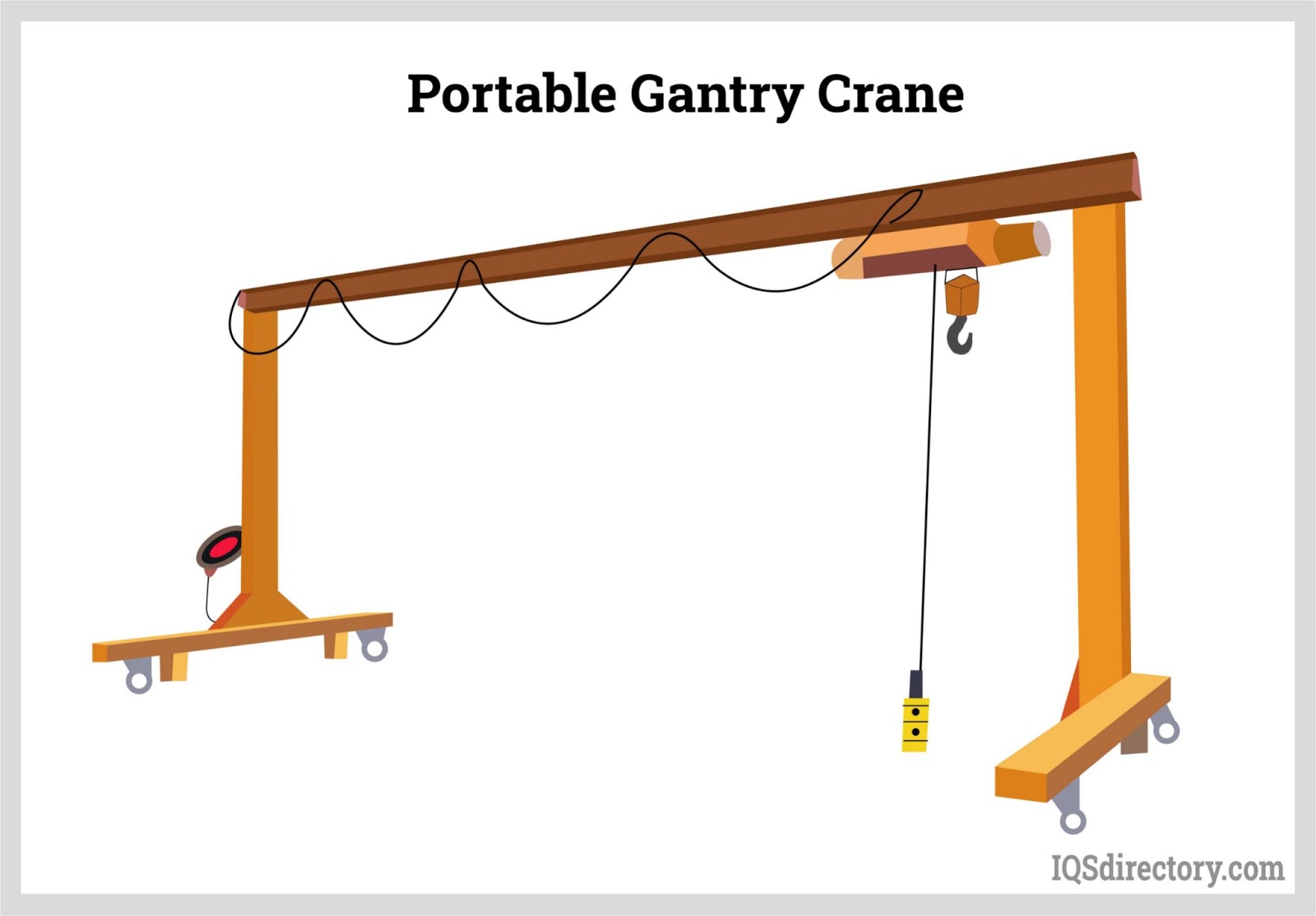

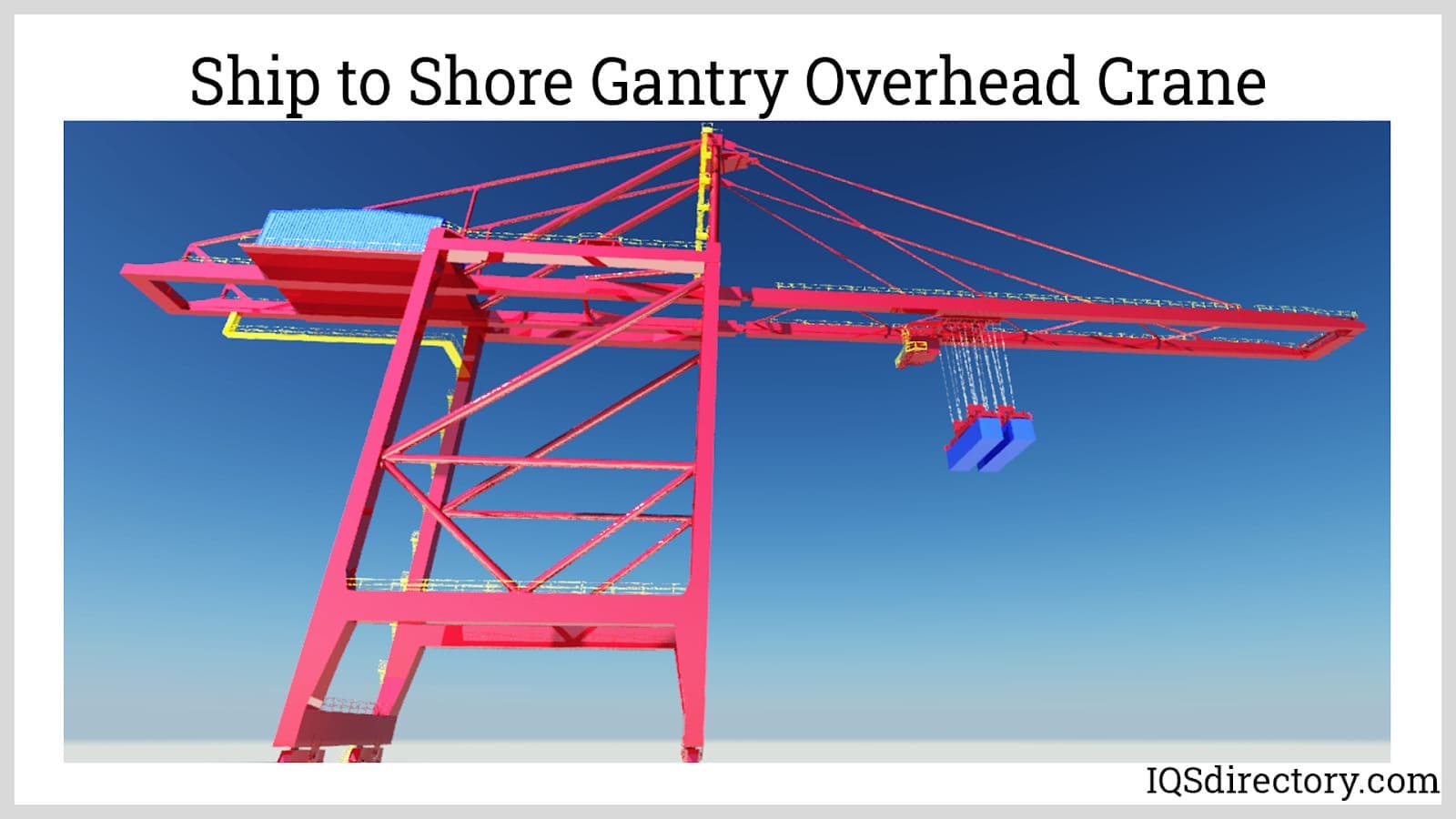

Gantry Cranes

In a gantry crane system, the bridge girder is supported by legs (not suspended), which may run on wheels or rails either on, or below, ground level. Gantry cranes are highly versatile and can be portable or fixed. They are commonly used outdoors, in shipyards, construction sites, and large warehouses where overhead crane runways are impractical.

- Capacity: Light-duty portable models to heavy-duty ship-to-shore gantries.

- Applications: Shipping yards, fabrication shops, outdoor storage, construction.

- Features: Mobility, adaptability, easy setup and teardown.

-

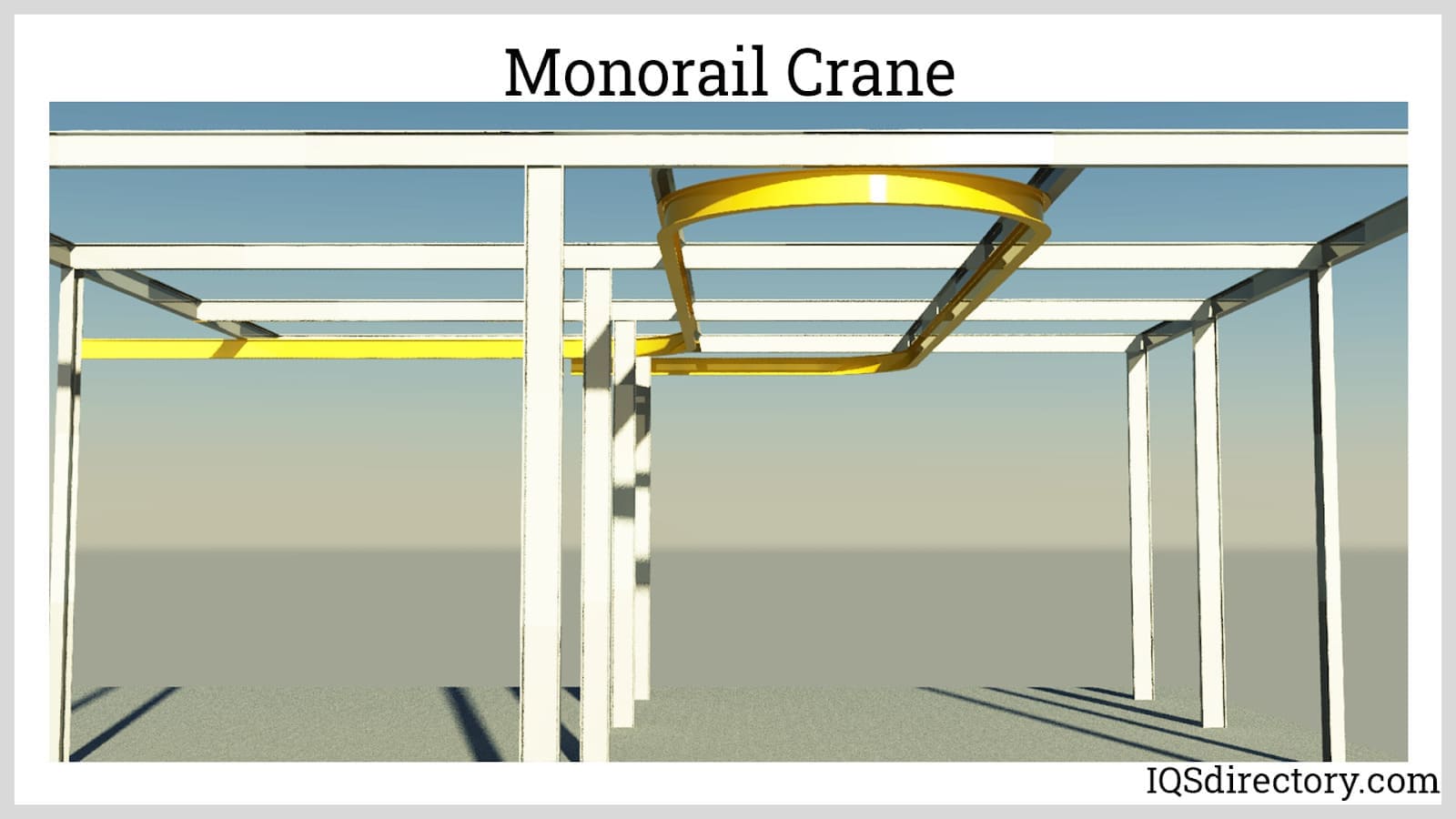

Monorail Cranes

Unlike bridge or gantry designs, a monorail crane uses a single, fixed I-beam track. The hoist and trolley run along this beam, following a predetermined path. Monorail crane systems are ideal for production lines and processes requiring repetitive, linear movement. The tracks of a typical monorail crane can be customized to fit unique facility layouts, including curves and switches.

- Capacity: Up to 10 tons (custom solutions available).

- Applications: Paint lines, assembly stations, material transfer processes.

- Features: Space efficient, flexible track layout, cost-effective for repetitive tasks.

-

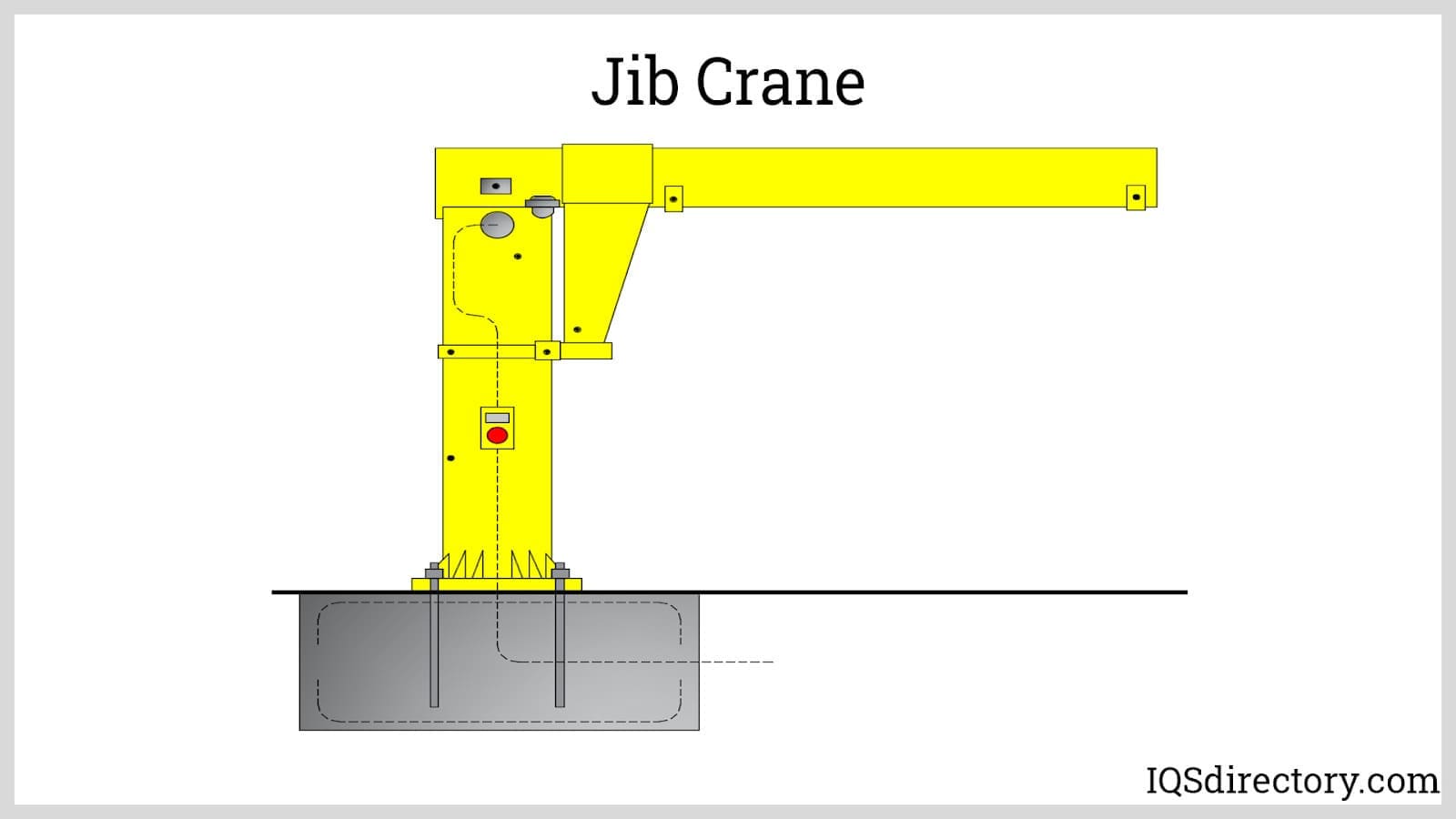

Jib Cranes

A jib crane consists of a horizontal boom attached to a vertical mast or wall. It does not require a runway system and can be either wall-mounted or free-standing. Jib cranes are ideal for workstations, machine shops, and small assembly areas where localized lifting is needed, complementing larger overhead crane systems.

- Capacity: Usually up to 5 tons.

- Applications: Loading docks, work cells, maintenance tasks.

- Features: 180° or 360° rotation, compact footprint, easy installation.

-

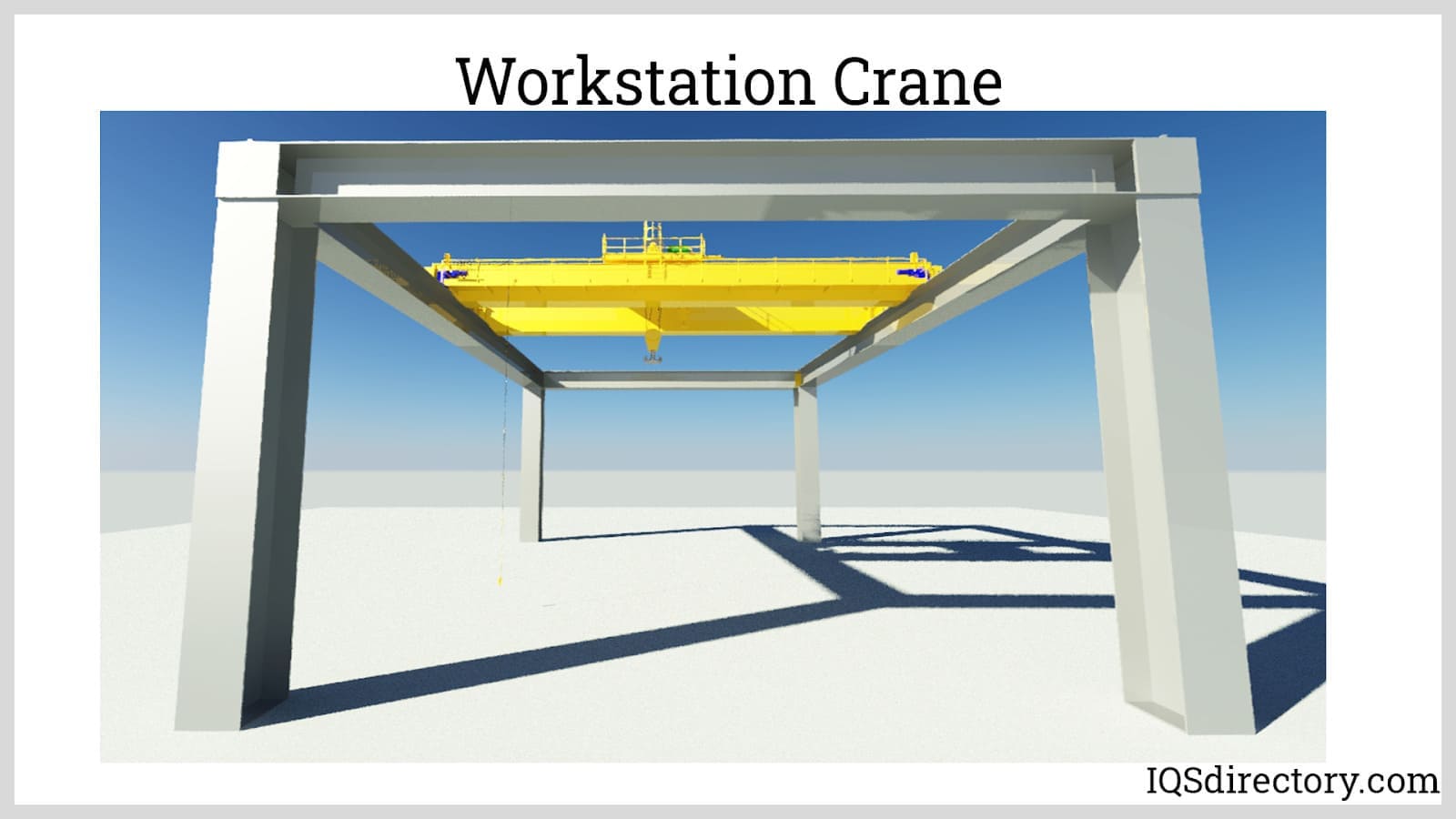

Workstation Cranes

Workstation cranes are lightweight, modular overhead lifting systems designed for ergonomic material handling in areas with limited space. With lifting capacities up to two tons, these cranes boost productivity, reduce operator fatigue, and minimize the risk of injury.

- Capacity: Up to 2 tons.

- Applications: Assembly lines, packaging, repair shops, laboratory environments.

- Features: Modular design, customizable layout, smooth and quiet operation.

Construction and Engineering Considerations for Overhead Cranes

How do you design an overhead crane for your facility? Beyond the weight and dimensions of the loads to be lifted, several technical and environmental factors must be considered when designing and selecting an overhead crane system. These include:

- Facility layout and building structure: Assess ceiling height, span requirements, and available support structures. Customized solutions are often needed for non-standard buildings or existing facilities.

- Duty cycle and frequency of use: Choose a crane design that matches the frequency and intensity of lifting operations (e.g., light-duty, moderate, or heavy-duty cycles).

- Environmental considerations: Specialized cranes may be required for hazardous environments, extreme temperatures, or outdoor use (e.g., explosion-proof, weather-resistant, or corrosion-resistant models).

- Material flow and workflow integration: Ensure the crane system supports your material handling processes, production flow, and storage needs.

- Bridge, trolley, and hoist: All overhead cranes, regardless of type, require these three fundamental building blocks for safe and efficient operation.

- Support configuration: In bridge and gantry cranes, the bridge spans two supports; in jib and cantilever cranes, the bridge (or boom) is supported at just one end.

Working Mechanism: How Does an Overhead Crane Operate?

- Power source: Overhead cranes are powered by hydraulics, internal combustion engines, or electric motors. The choice depends on load requirements, duty cycle, and operational environment.

- Trolley and movement: The hoist and crane hook are moved along the bridge by a mechanical or electrically-driven system known as the trolley. This allows for precise load positioning.

- Hoist operation: The hoist is responsible for lifting and lowering the crane attachment, such as a hook, grapple, fork, or auger.

- Lifting mechanism: The main electric, internal combustion, or hydraulic lift of the crane, located at the bottom or top of its support, is connected to the crane attachment by a wire rope or nylon cables. Electric motors are common for lighter applications, while hydraulic or diesel-powered cranes handle the heaviest loads.

- Controls and automation: Modern overhead cranes often feature variable frequency drives (VFDs), programmable logic controllers (PLCs), anti-sway technology, and remote operation for improved safety and productivity.

Key Benefits of Using Overhead Cranes

Overhead cranes deliver a wide range of advantages that make them a preferred choice for industrial material handling. What are the main benefits of overhead cranes?

- Increased productivity: Quickly transferring bulky objects from storage to the shipping port or through manufacturing processes is a key advantage, reducing cycle times and operational delays.

- Reduced risk of damage: Overhead cranes lessen the potential for material or product damage by lifting loads above obstacles, minimizing contact with other equipment or structures.

- Lower operating costs: Automating heavy lifting tasks reduces labor requirements, decreases injury rates, and improves workflow efficiency, leading to significant cost savings over time.

- Sustainability: Many modern cranes utilize energy-efficient motors and regenerative drives, providing a “green” solution that helps reduce environmental impact.

- Space optimization: Overhead cranes free up valuable floor space, enabling more efficient storage layouts and safer traffic flow within the facility.

- Customizability and scalability: Modular designs, adjustable spans, and a wide range of accessories make it easy to tailor crane systems to evolving operational needs.

Common Applications for Overhead Cranes

Overhead cranes are essential in many industries where heavy lifting, precise positioning, or repetitive material movement is required. Where are overhead cranes most commonly used?

- Warehousing and logistics: Equipment, supplies, and materials are constantly moved, set up, and prepared for shipping and receiving.

- Metal production and fabrication: Overhead cranes are crucial in refining steel and other metals like copper and aluminum. They handle hot and heavy materials throughout the production process, from casting to finishing.

- Automotive and large-equipment assembly: Automotive plants and equipment manufacturers use overhead cranes to lift and move unfinished assemblies or components through various stages of production.

- Shipping, rail, and transportation: Large, bulky items are efficiently loaded onto or offloaded from cars, trains, or trucks for distribution. Overhead cranes enable fast, safe, and precise cargo handling at ports and terminals.

- Maintenance and repair operations: Overhead cranes gently move and arrange heavy items for easier access during repairs of punch presses, stamping machines, or other industrial equipment.

- Energy and infrastructure: Power plants, wind turbine facilities, and infrastructure projects rely on overhead cranes for installing and servicing heavy equipment.

- Mining and raw materials handling: Overhead cranes transport raw materials, minerals, and aggregates within processing plants and storage facilities.

- Paper mills, aerospace, and beyond: From paper rolls to aircraft parts, overhead cranes are used wherever large, heavy, or awkward items require safe, efficient movement.

Looking for industry-specific overhead crane solutions? Browse crane solutions by industry application.

How to Choose the Right Overhead Crane Supplier or Manufacturer

Selecting the best overhead crane company is a critical step in ensuring you receive a reliable, compliant, and cost-effective material handling solution. Here are key factors to consider when researching overhead crane suppliers:

- Experience and expertise: Evaluate the manufacturer’s track record in designing, engineering, and installing crane systems for your specific industry or application.

- Customization and engineering support: Look for suppliers who offer tailored solutions, including custom spans, capacities, and controls.

- Safety compliance: Ensure the company adheres to OSHA, ASME, and other relevant safety standards.

- After-sales support and maintenance: Consider providers who offer installation, inspection, maintenance, and repair services.

- Technology and innovation: Does the supplier offer advanced features like automation, remote monitoring, or energy-efficient drives?

- Warranty and lifecycle costs: Compare warranty coverage, spare parts availability, and total cost of ownership.

To make sure you have the most positive outcome when purchasing overhead cranes from an overhead cranes supplier, it is important to compare at least 5 or 6 companies using our list of overhead crane suppliers. Each overhead crane company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each overhead crane business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple overhead crane businesses with the same quote.

Ready to find the right overhead crane partner? Request multiple quotes from leading overhead crane manufacturers and compare options today.

Frequently Asked Questions About Overhead Cranes

- What is the difference between a single girder and double girder overhead crane? Single girder cranes are lighter, more economical, and suitable for lighter loads and shorter spans, while double girder cranes offer higher capacities and greater span lengths for heavy-duty applications.

- Can overhead cranes be automated? Yes, many modern overhead cranes support automation features such as programmable travel, anti-sway technology, and integration with warehouse management systems (WMS).

- How do I determine the correct capacity for my overhead crane? Calculate the maximum weight to be lifted, consider the duty cycle, and consult with a qualified crane engineer or manufacturer for proper sizing.

- What maintenance is required for overhead cranes? Routine inspections, lubrication, part replacement, and testing of safety features are crucial for safe operation and compliance with safety standards.

- Are custom and retrofit crane solutions available? Absolutely. Leading manufacturers offer custom-engineered crane systems and can retrofit existing equipment to meet new requirements or safety standards.

Get Expert Guidance for Your Overhead Crane Project

Whether you are upgrading an existing facility, designing a new production line, or looking for ways to improve safety and efficiency, choosing the right overhead crane system is a major investment. Our team of industry experts can help you assess your needs, compare options, and connect with leading manufacturers for tailored solutions.

Start your search:

- Read our step-by-step buying guide for overhead cranes

- Request competitive quotes from top overhead crane suppliers

Still have questions? Contact our overhead crane experts for personalized advice and recommendations based on your specific requirements.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches